[Adachi Brand] Grace Embed Co., Ltd., the largest embroidery factory in Tokyo, will be exhibiting at the “Tokyo International Gift Show” again this year! An embroidery processing company that started out as a latecomer, take a look at the outstanding perfection achieved through technical research and the spirit of challenging new embroidery!

Adachi brand Press release: February 6, 2025 GraceEmb Co., Ltd., the largest embroidery factory in Tokyo, will be exhibiting at the “Tokyo International Gift Show” again this year! An embroidery processing company that started out as a latecomer, take a look at the outstanding perfection achieved through technical research and the spirit of challenging new embroidery! Grace Emb Co., Ltd. will be exhibiting as the “Adachi Brand” at the “99th Tokyo International Gift Show” to be held at Tokyo Big Sight for three days from Wednesday, February 12, 2025 to Friday, February 14, 2025. The embroidery processing company was founded in 1985 in Okino, Adachi Ward, and was certified as an Adachi brand in 2008. As the largest embroidery factory in Tokyo, the company’s strength lies in its ability to embroider a variety of materials using a variety of techniques such as Sagara embroidery, sequin embroidery, and 3D embroidery, with 20 machines and 12-color (12-color thread can be used to embroidery 20 items at once) machines. We will explore the meaning behind joining the Adachi brand and how an embroidery processing company that started out as a latecomer has outperformed its competitors.

https://prcdn.freetls.fastly.net/release_image/136487/88/136487-88-3e8e841282e1e14992e213c3d9bf973f-1447×1929.png Unsure about participating in “Adachi Brand” “Is there really any benefit or need for us?” That’s how Hirofumi Okabe, representative of Grace Enbu, initially felt about the Adachi brand. At the end of 2006, at the year-end party of the Adachi Cross-Industry Exchange

Association Mirai Club, Mr. Okabe heard from a ward representative that an “Adachi Brand” would be launched next fiscal year with the aim of further developing industry in the ward and improving the image of Adachi Ward by promoting it nationwide and expanding its network, but Mr. Okabe hesitated to apply. The reason for this was that for an embroidery processing company that already boasts one of the largest scale and production levels in Tokyo, the name “Adachi” was necessary. While members of the Future Club expressed their intention to participate one after another, Mr. Okabe ultimately did not raise his hand in the first round of recruitment. Later, when Adachi Brand Certification Company was given the opportunity to exhibit at the Tokyo International Gift Show, Mr. Okabe’s thoughts changed and he applied and was certified by Adachi Brand. “When I previewed the venue for the gift show, I realized that it would be difficult to attract customers by simply arranging products.I thought it was important to get customers to stop by first.The following year, I applied and declared that if I was accepted, I would bring something that moved to the venue,” he recalls. As a result, Mr. Okabe purchased a small 1.7 million yen embroidery machine with his own money that he could bring to the venue.His drastic decision and impactful demonstration were successful, and the gift show

successfully attracted customers and became a foothold that would greatly contribute to future sales. Read the trends of the times and advance with an enterprising spirit Mr. Hirofumi Okabe, born in 1945, was born and raised in Adachi. Born as the eldest son of parents who run a slipper manufacturing business, he quit his previous job at an automobile company and started working for his family’s company. With a strong belief that “Be the head of a dog rather than the tail of a tiger,” he enthusiastically joined the slipper manufacturing company. Using the production management technology cultivated at an automobile company, the company introduced equipment such as the “carry-in belt conveyor” that reduced the strain on workers’ bodies, and for a time, sales increased significantly and the company reached its peak of prosperity. However, from the 1960s, about 15 years after I joined the company, as people started to move away from Japanese clothing, local zori manufacturers started making use of their know-how and moved into the slipper manufacturing industry. “At that time, there was a large disparity in labor costs between Tokyo and the region, and work gradually moved to the regions, causing our company’s sales to decline,” says Okabe. It was a difficult time, but the only saving grace was that slippers with an embroidered English logo became a hit product. At that time, the embroidery work was outsourced to an embroidery maker friend of Mr. Okabe’s, but the company declined because they were too busy working on embroidery for clothing and could not handle slippers. “While our sales were declining, we had so many orders that we couldn’t keep up with production, but we couldn’t find any other embroidery companies to work with, so we were worried.”

https://prcdn.freetls.fastly.net/release_image/136487/88/136487-88-63705276a34b59bd65142fd3d2059b85-1144×1459.jpg Leading a late-starting embroidery processing company to success After thinking about it, Mr. Okabe comes to a conclusion. “At the same time as I felt troubled, I became very interested in the “embroidery process”, which is an overwhelming amount of work.I consulted a friend of mine who works at an embroidery processing company to see if it would be possible to install an embroidery machine and do embroidery not only for slippers, but also for clothing.My friend, who was unable to do anything, agreed to subcontract his company, and he was able to give me, an amateur who doesn’t know what’s left and right, guidance on embroidery.”

https://prcdn.freetls.fastly.net/release_image/136487/88/136487-88-c7b4dcdb09e3f9d28841151ba43bd7cf-1477×1108.jpg After that, embroidery work continued to grow steadily, and slipper production, the main business, continued to decline, forcing manufacturers to lower purchasing prices. “At the time, I think it cost about 1,000 yen for three pairs.However, if I were to pay more than that, there would be a problem with labor costs, and above all, my parents’ pride in making good products with sincerity would not allow it.” After thinking about it, when the sales ofembroidery and slippers matched, I took the plunge and decided to quit producing slippers and focus on the embroidery processing business. At first, she began embroidery as a subcontractor, but gradually began to explore ways to become independent. It was even more encouraging to see an increase in the number of companies with which we could do business directly. However, we were a latecomer to the embroidery processing industry, and even if we wanted to enter the industry, all of the companies that needed embroidery were older companies. “We did not want to operate at a lower price than the embroidery processing company we had been working with. Therefore, we decided to compete by developing embroidery technology that no other company could.The latest technology that expresses technique and delicacy. We used machines to make things more attractive, then introduced machines that could embroidery finished products, and introduced machines that eliminated the hassle of thread cutting to ensure quick delivery. Armed with new technology that brings high quality, we pioneered new developments.” Fortunately, Mr. Okabe is a self-proclaimed “science brain” and was able to easily accept the task of handling new machines. He also says that he put a lot of effort into developing new businesses, not just from a technical standpoint, but also by “using his feet.” “About 10 years ago, during the bubble period, designer brand apparel was on the rise. I would often go to Harajuku during holidays, and whenever I found a store that seemed to be trending, I would bring samples and do business there. I didn’t know where the headquarters with planning and design functions was, so I asked the shop clerk at the store to introduce me to the person in charge.”

https://prcdn.freetls.fastly.net/release_image/136487/88/136487-88-e1c1e7317cd9ea16b7942a41be0cdc9e-1477×1108.jpg Creative sensibility of embroidering on things other than cloth Most of the demand for embroidery is for clothing. Thanks to corporate efforts and Mr. Okabe’s resourcefulness, the restaurant has overcome many challenges and is now said to be the best in Tokyo. However, the current situation is that 5% of Japanese apparel is produced domestically, with the rest produced overseas.

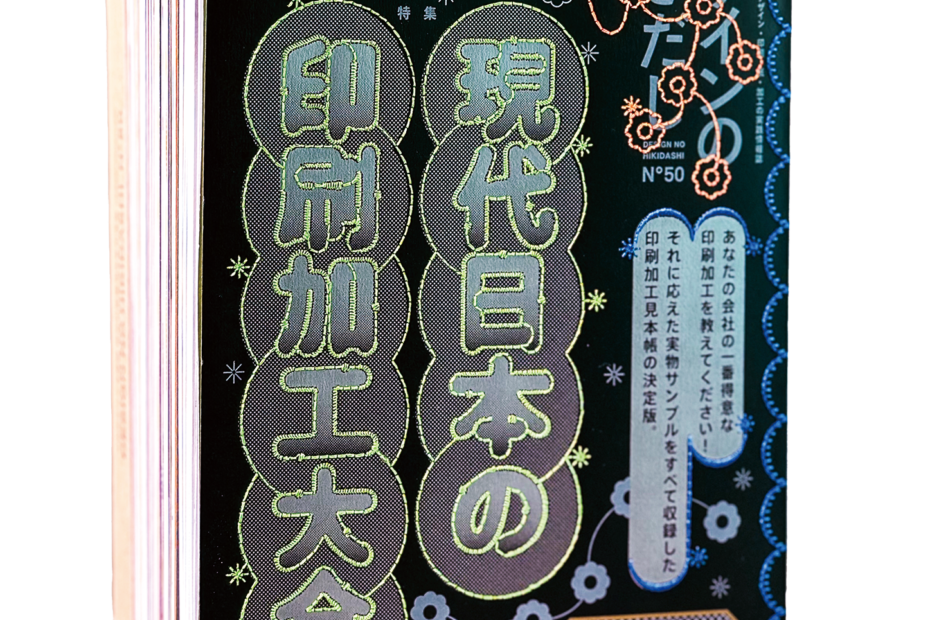

https://prcdn.freetls.fastly.net/release_image/136487/88/136487-88-0b75e37d1af9ed6fd73fcd098b75de73-3900×2600.jpg “We have introduced special machines and devised ways to embroider even imported finished products, and we are also devising and researching embroidery on fabrics other than cloth.For example, we have connected with many leather product manufacturers in Adachi Ward, We also do embroidery on thick leather such as schoolbags. Also, in the book for designers, “50 Design Drawers” (Graphic-sha), “Grace Embroidery” on paper decorated the design of the book.”

https://prcdn.freetls.fastly.net/release_image/136487/88/136487-88-14b3830c09698f0207ec7533dc7aee51-3900×2600.jpg The destination of embroidery processing companies: to the next generation Currently, “Grace Enbu” has 15 employees. Most of our business partners and employees are residents of Adachi Ward. Five of our employees are family members. Mr. Okabe says, “Everyone enjoys embroidering different characters and logos of famous brands every day, and they all come to work with enthusiasm.My three children also work together with me in this job.We have even been certified as an excellent company by a corporate consultant.”The work environment is something that Mr. Okabe is proud of. Kenji, the second son who is in charge of development in the design department, says, “I think my father is truly amazing.I hope he can further develop the work he has done so far.” What are Mr. Okabe’s future aspirations? When asked, he concludes by saying, “When a customer requests it, we want to hone our skills so that we don’t have to say that we can’t embroider on any material, strive to maintain and improve quality that is second to none, and build absolute trust with our business partners.” Currently, there are only two companies in Japan that manufacture embroidery machines. Since all embroidery processing companies use almost the same machines, why is “Grace Embroidery” chosen? I feel that the secret is summarized in these words.

https://prcdn.freetls.fastly.net/release_image/136487/88/136487-88-fa3df47b59e1f7c3e35c3249178a51d6-1035×1387.jpg We will also be exhibiting as the Adachi Brand at the 99th Tokyo International Gift Show, which will be held at Tokyo Big Sight for three days from Wednesday, February 12th to Friday, February 14th, 2025. At the “SOZAI Exhibition” corner of the gift show, please take a look at the outstanding perfection achieved through technical research and the spirit of taking on new embroidery challenges at Grace Embroidery Co., Ltd. We look forward to your visit. Company information Grace Emb Co., Ltd. http://grace-emb.co.jp/ Company name: Grace Emb Co., Ltd. Address: 2-14-25 Kono, Adachi-ku, Tokyo Phone number: 03-3890-6789 Representative: Hirofumi Okabe Business content: Embroidery processing of textile products and others The Adachi Brand is a project that aims to further develop the industry in the ward and improve the image of Adachi Ward by recognizing the excellent products and technologies of companies within the ward and disseminating their excellence throughout the country. “Grace Enbu Co., Ltd.” is a company certified as this “Adachi

brand.” ________________________________________________________________________________ For inquiries regarding coverage and other published information, please contact the Manufacturing Promotion Section of the Industrial Promotion Division, Industrial Economics Department, Adachi Ward Office, which is also the administrative office of “Adachi Brand”. Manufacturing Promotion Section, Industrial Promotion Division, Industrial Economy Department, Adachi City Hall Phone number: 03-3880-5869 Fax: 03-3880-5605 Adachi brand official website https://adachi-brand.jp/

This article was partly generated by AI. Some links may contain Ads. Press Release-Informed Article.